Since the foundation in 1998 AllCAD Technologies was always committed to find new and perfect solutions for it’s design tools and NOT to copy competitors. This philosophy lead to our ProLace Embroidery Design & Punching Systems, which are unique in many respects.

Now AllCAD continues this tradition as trendsetter and opens completely new prospects in design development, which result in massive increase of efficiency and productivity in the whole creative process.

Traditional way of design development

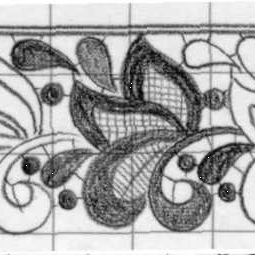

The designer creates a rough sketch of his idea. This hand sketch can be elaborated manually to a presentation sketch or it can be scanned and traced with a Graphic Program. Some modern designers create their sketch directly with a Graphic Program. In all cases the result is a flat and dull sketch.

A sketch is normally not good enough to be presented to the customer, so a sample must be produced.

A sketch is normally not good enough to be presented to the customer, so a sample must be produced.

The sketch comes to the design department where it must be traced again and elaborated to a technical design.

The technical design will be passed to the punching department, where the design is converted in machine readable stitch.

Finally the production can produce a sample of the design.

Conclusion

After about 1 week the sample can be presented to the customer, along with the calculated price.

If lucky, an order follows, but in many cases the customer requests modifications or a cheaper price and the whole process Editing the Design > Drafting > Punching > Sampling starts again.

Design development with ProLace

With ProLace the designer can directly start drawing the sketch with pen and tablet. No paper is required and thus scanning and retracing are not necessary.

With powerful automatic stitches the raw sketch can be elaborated to the technical design. With ProView this not yet punched embroidery draft can be used to generate an Embroidery Simulation.

After short time the sales department can already present the image and and estimated price to the customer.

After short time the sales department can already present the image and and estimated price to the customer.

If modifications are required they can be applied to the draft and a new simulation along with the new price can be presented to the customer.

Once the customer accepts design and price, it can be passed to the puncher, who directly continues with the same file. No tracing and no drafting are necessary anymore, just the embroidery order has to be defined and undrelay and machine commands have to be added.

Finally the stitch data can be generated.

Conclusion

After just 2 days of development the production can already start.

This is a saving of at least 50% of time plus the saved sampling cost.

If the first version of the design is not accepted by the customer, the saving is even much higher.